Working Principle

Product Introduction

Working Principle

The power is transferred from the motor to the shaker drive shaft and gear shaker (speed ratio is 1) through the triangular belt to realize the three axes rotating at the same speed and generate the exciting force. The shaker is connected to the screen box with high-strength bolts to generate elliptical motion. The material on the screen surface with the screen machine high-speed elliptical movement, quickly stratification, screening, forward to complete the classification of materials.

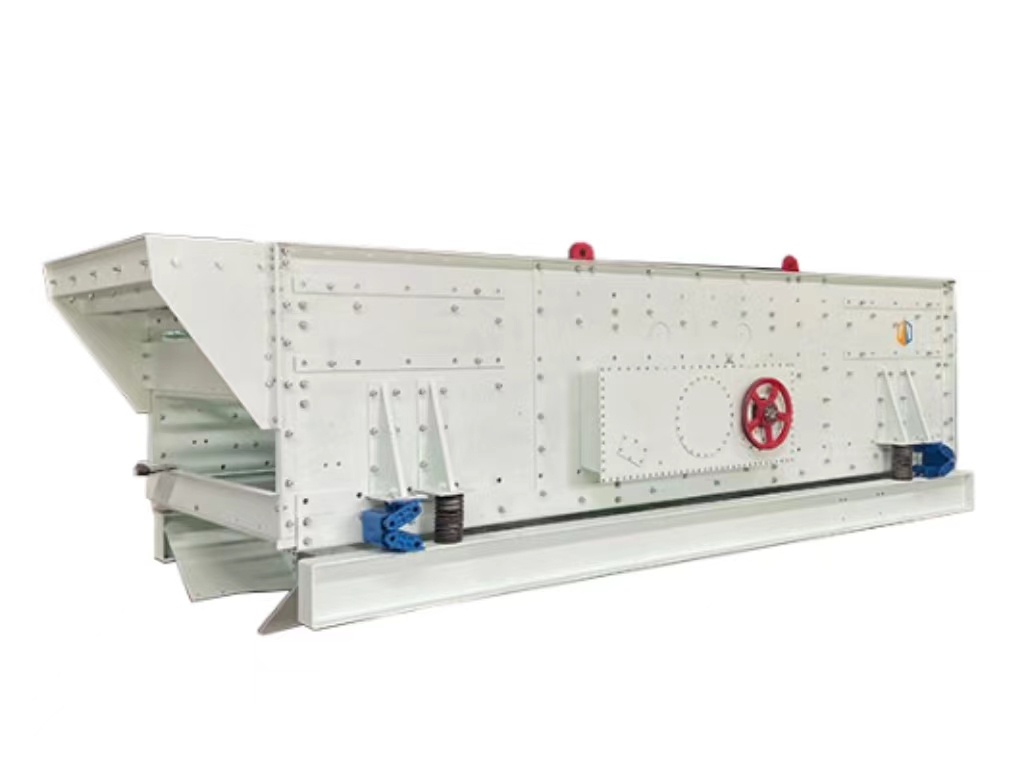

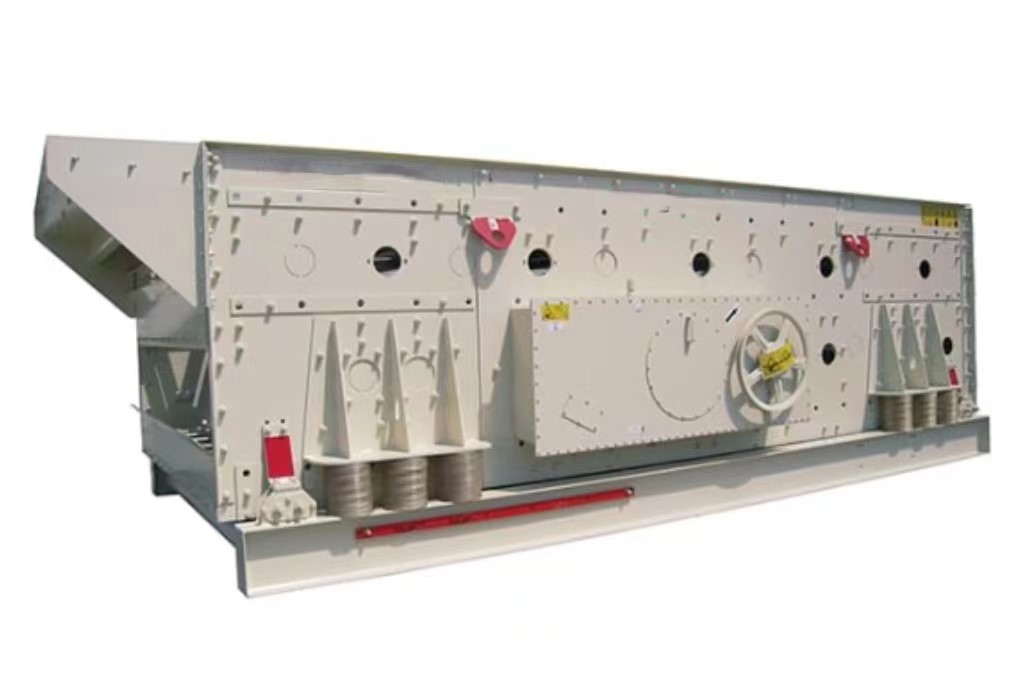

Product Introduction

The three-axis horizontal screen is also called 0∘ vibrating screen, which is a new multi-layer vibrating screen, which is installed horizontally and occupies a small space on the site. Good screening, large processing capacity, high screening efficiency; Elliptical trajectory, adjustable amplitude, small installation height, vibration trajectory can be selected according to the actual material condition, more advantages for difficult screening materials, is a mine, sand and stone production line, mobile screening station supporting equipment.

Three axis horizontal screen highlights the advantage

Reliable structure, strong exciting force

Due to its horizontal installation, it effectively reduces the height of the unit and can well meet the needs of large and medium-sized mobile screening groups.

High screening efficiency, large processing capacity, low vibration noise

Three-axis drive forced synchronous excitation, can make the screen to obtain a stable working state, large processing capacity.

Durable, easy to maintain, safe to use

The three-axis drive improves the stress state of the screen frame, reduces the load of a single bearing, the side plate is stressed evenly, reduces the stress concentration point, improves the stress condition of the screen frame, and improves the reliability and life of the screen machine.

Elliptical trajectory; adjustable amplitude

The three-axis drive can make the screen produce the ideal elliptical motion, which has the advantages of circular vibrating screen and linear vibrating screen, and the elliptical track and amplitude can be adjusted, which can select the vibration track according to the actual material condition, and has more advantages for the material that is difficult to screen. Bearing oil lubrication, effectively reduce the bearing temperature, improve the life; With the same screening area, the machine’s output can be increased by 1.3-2 times.

Reliable structure, strong exciting force

Due to its horizontal installation, it effectively reduces the height of the unit and can well meet the needs of large and medium-sized mobile screening groups.

High screening efficiency, large processing capacity, low vibration noise

Three-axis drive forced synchronous excitation, can make the screen to obtain a stable working state, large processing capacity.

Durable, easy to maintain, safe to use

The three-axis drive improves the stress state of the screen frame, reduces the load of a single bearing, the side plate is stressed evenly, reduces the stress concentration point, improves the stress condition of the screen frame, and improves the reliability and life of the screen machine.

Elliptical trajectory; adjustable amplitude

The three-axis drive can make the screen produce the ideal elliptical motion, which has the advantages of circular vibrating screen and linear vibrating screen, and the elliptical track and amplitude can be adjusted, which can select the vibration track according to the actual material condition, and has more advantages for the material that is difficult to screen. Bearing oil lubrication, effectively reduce the bearing temperature, improve the life; With the same screening area, the machine’s output can be increased by 1.3-2 times.

Performance Parameter

| Model | Decks | Screen Size (mm) | Max Feed Size (mm) | Capacity (t/h) | Frequency (r/min) | Power (kW) | Dimensions |

|---|---|---|---|---|---|---|---|

| (L×W×H mm) | |||||||

| 2ZTS1550 | 2 | Φ500×Φ500 | 120 | 75-300 | 13-16 | 18.5 | 5700×2240×1470 |

| 2ZTS2060 | 2 | 2000×6000 | 120 | 100-400 | 13-16 | 22 | 6870×2750×1470 |

| 2ZTS2260 | 2 | 2200×6000 | 150 | 110-440 | 13-16 | 30 | 6870×3660×1710 |

| 2ZTS2460 | 2 | Φ2400×Φ6000 | 150 | 120-480 | 13-16 | 30 | 6870×3150×1470 |

| 3ZTS1550 | 3 | 1500×5000 | 120 | 70-270 | 13-16 | 22 | 5700×2240×1870 |

| 3ZTS2060 | 3 | 2000×6000 | 120 | 90-360 | 13-16 | 30 | 6870×2750×1870 |

| 3ZTS2260 | 3 | 2200×6000 | 150 | 100-390 | 13-16 | 37 | 6870×3742×2150 |

| 3ZTS2460 | 3 | 2400×6000 | 150 | 110-430 | 13-16 | 37 | 6870×3150×1870 |

| 4ZTS2060 | 4 | 2000×6000 | 150 | 100-400 | 13-16 | 37 | 6870×3700×2666 |